CNC milling, CNC turning and grinding

CNC milling, CNC turning and grinding

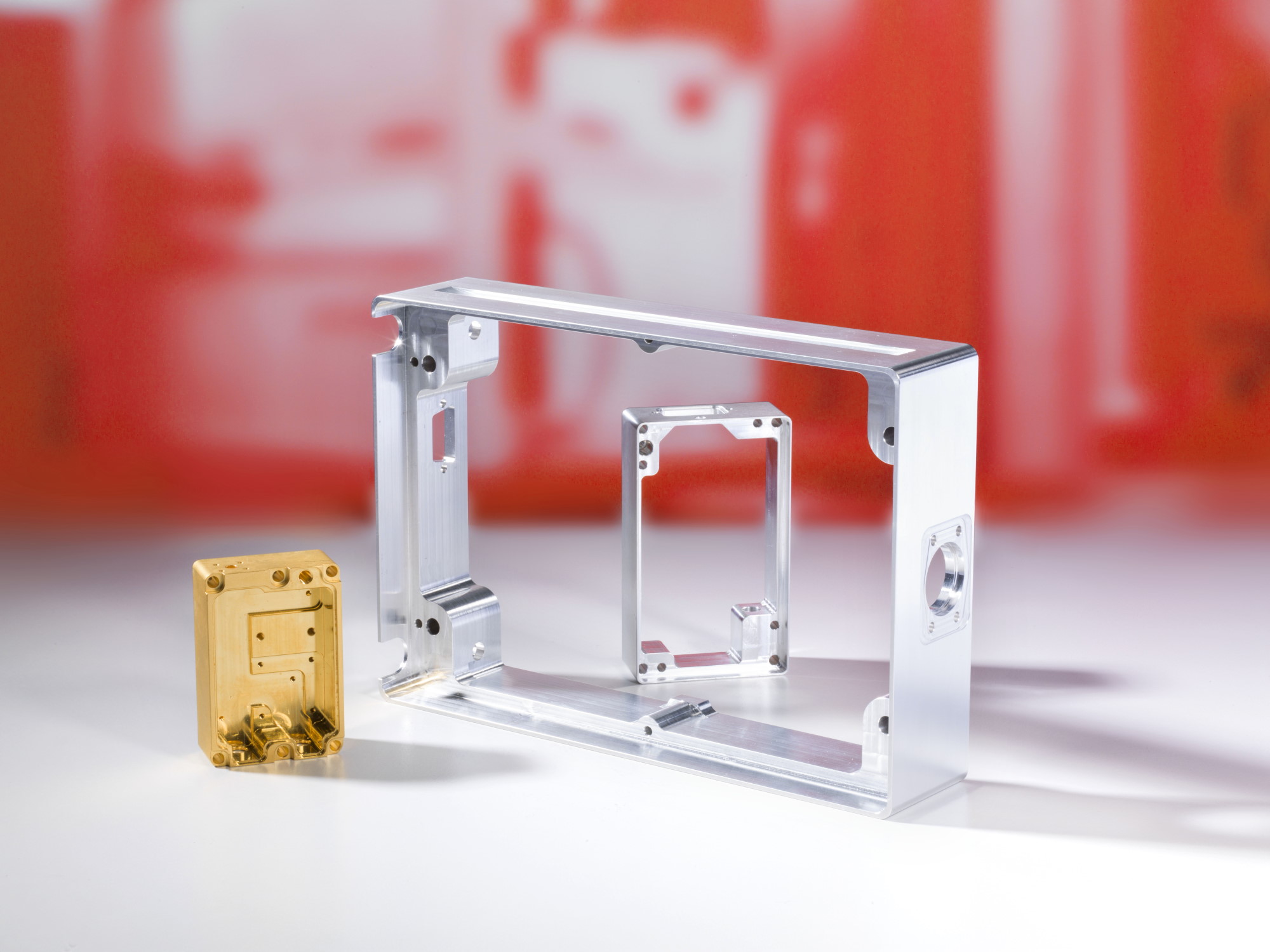

As a specialist for machining production, we offer you top performance in milling, turning, grinding and much more. With a machine park of more than 50 CNC machines, we offer our customers a large vertical range of manufacture and a high production capacity. The broad spectrum allows us to manufacture both large components and small parts with the highest precision.

Due to our wide range of applications, we have extensive experience in processing a wide variety of material compositions. The materials are procured exclusively from qualified suppliers, whereby we guarantee complete documentation of the traceability of the finished products.

As a specialist for machining production, we offer you top performance in milling, turning, grinding and much more. With a machine park of more than 50 CNC machines, we offer our customers a large vertical range of manufacture and a high production capacity. The broad spectrum allows us to manufacture both large components and small parts with the highest precision. Due to our wide range of applications, we have extensive experience in processing a wide variety of material compositions. The materials are procured exclusively from qualified suppliers, whereby we guarantee complete documentation of the traceability of the finished products. |

CNC milling

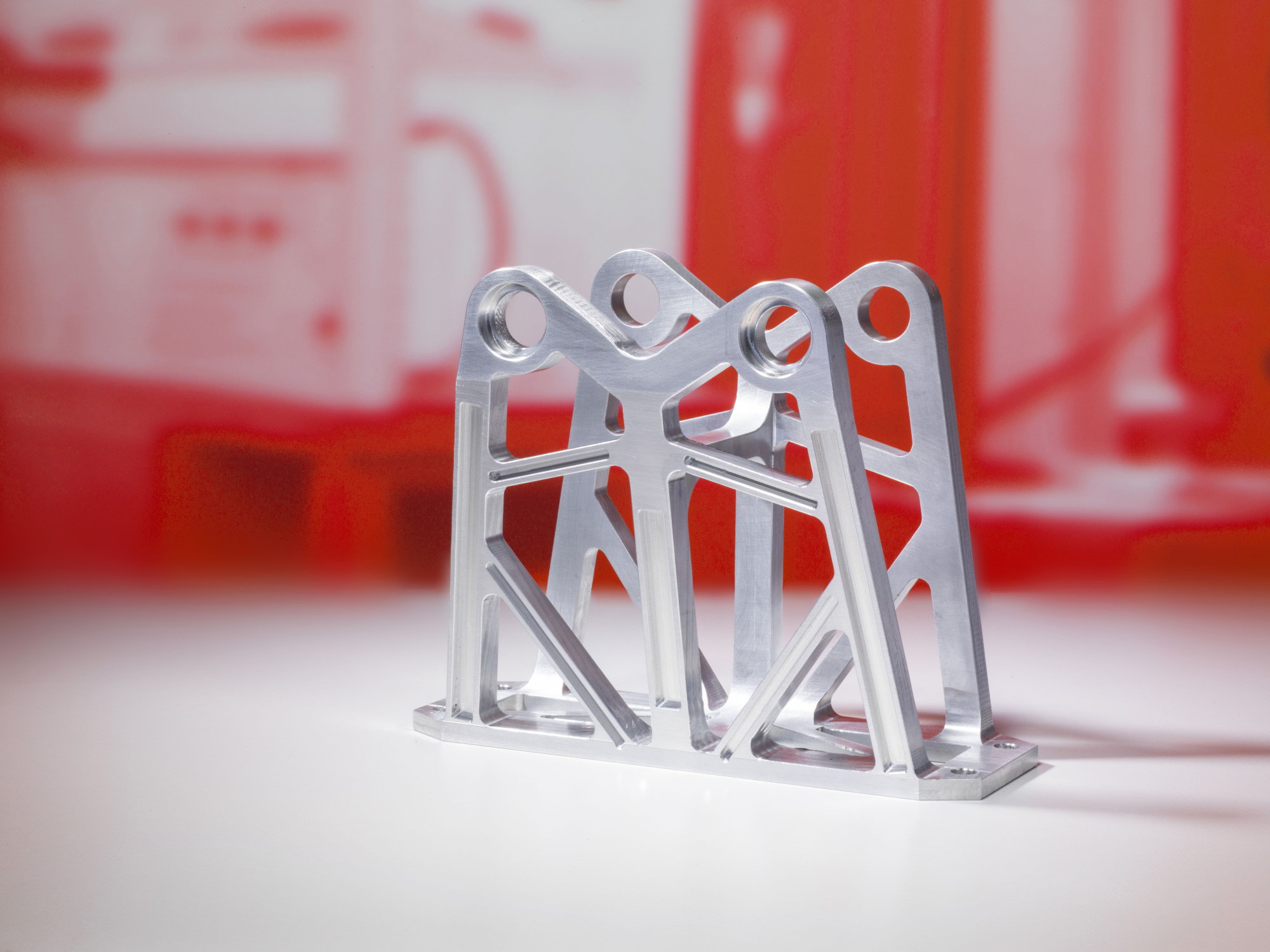

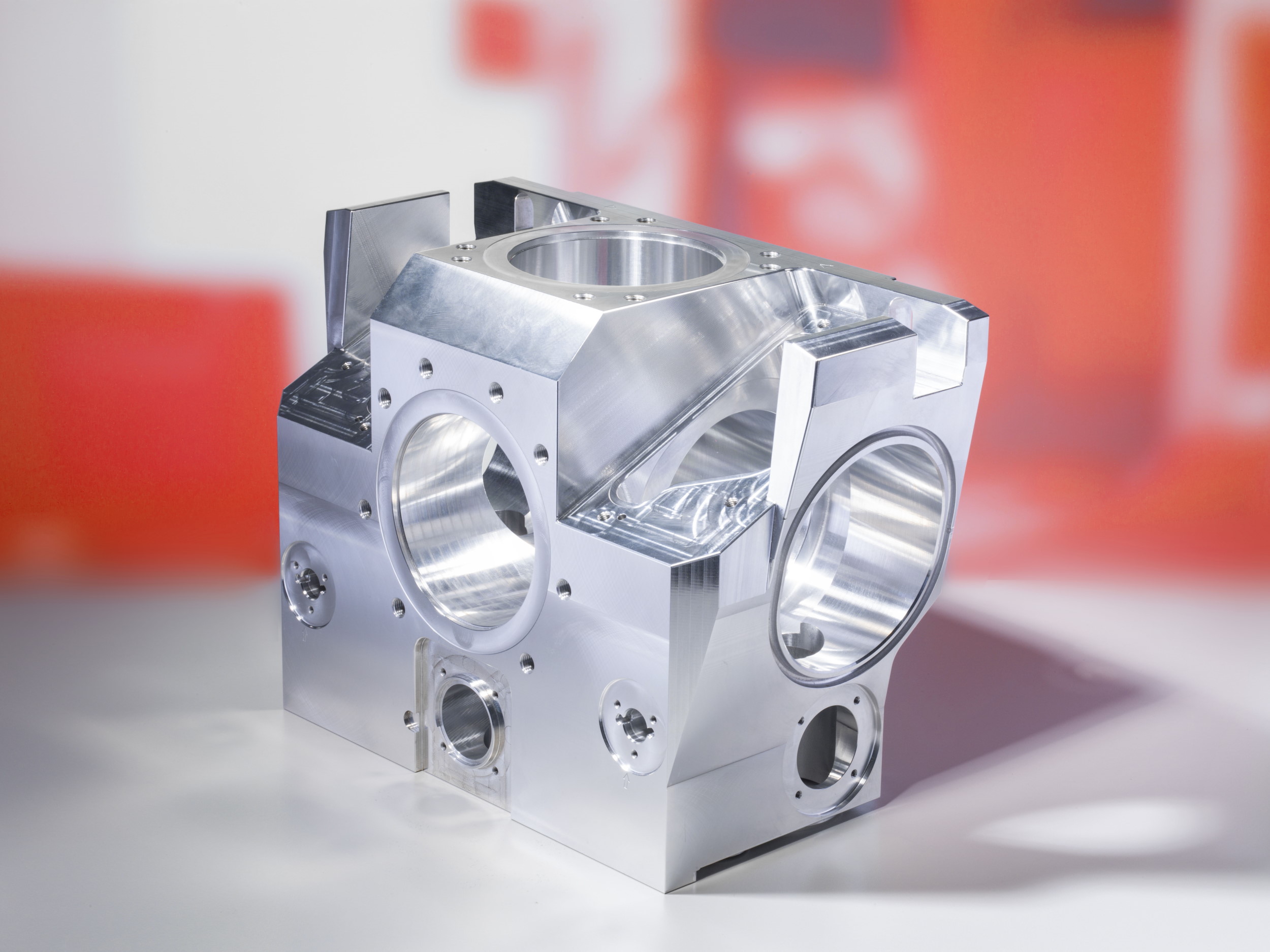

On various horizontal and vertical machines, we manufacture precision components from almost all metallic materials. In total, we process over 200 tons of steel, 100 tons of aluminium, 100 tons of stainless steel and various other materials per year. On highly dynamic milling centres with multi-pallet systems and 240 tool places, aluminium components are produced in best quality and also economically. Stable horizontal centres enable high cutting capacities in the steel and stainless-steel sector and simple, flexible clamping devices guarantee fast set-up. Everything is geared to the economical production of precision parts in series and in best quality.

- Horizontal machines

- Vertical machines

- Fully automatic processing machines

- Long-bed machines

- Machining dimensions up to 1,500 x 1,500 x 6,000mm

- Loading/unloading robots

- 3-shift operation possible

- Small/large series

CNC millingOn various horizontal and vertical machines, we manufacture precision components from almost all metallic materials. In total, we process over 200 tons of steel, 100 tons of aluminium, 100 tons of stainless steel and various other materials per year. On highly dynamic milling centres with multi-pallet systems and 240 tool places, aluminium components are produced in best quality and also economically. Stable horizontal centres enable high cutting capacities in the steel and stainless-steel sector and simple, flexible clamping devices guarantee fast set-up. Everything is geared to the economical production of precision parts in series and in best quality.

|

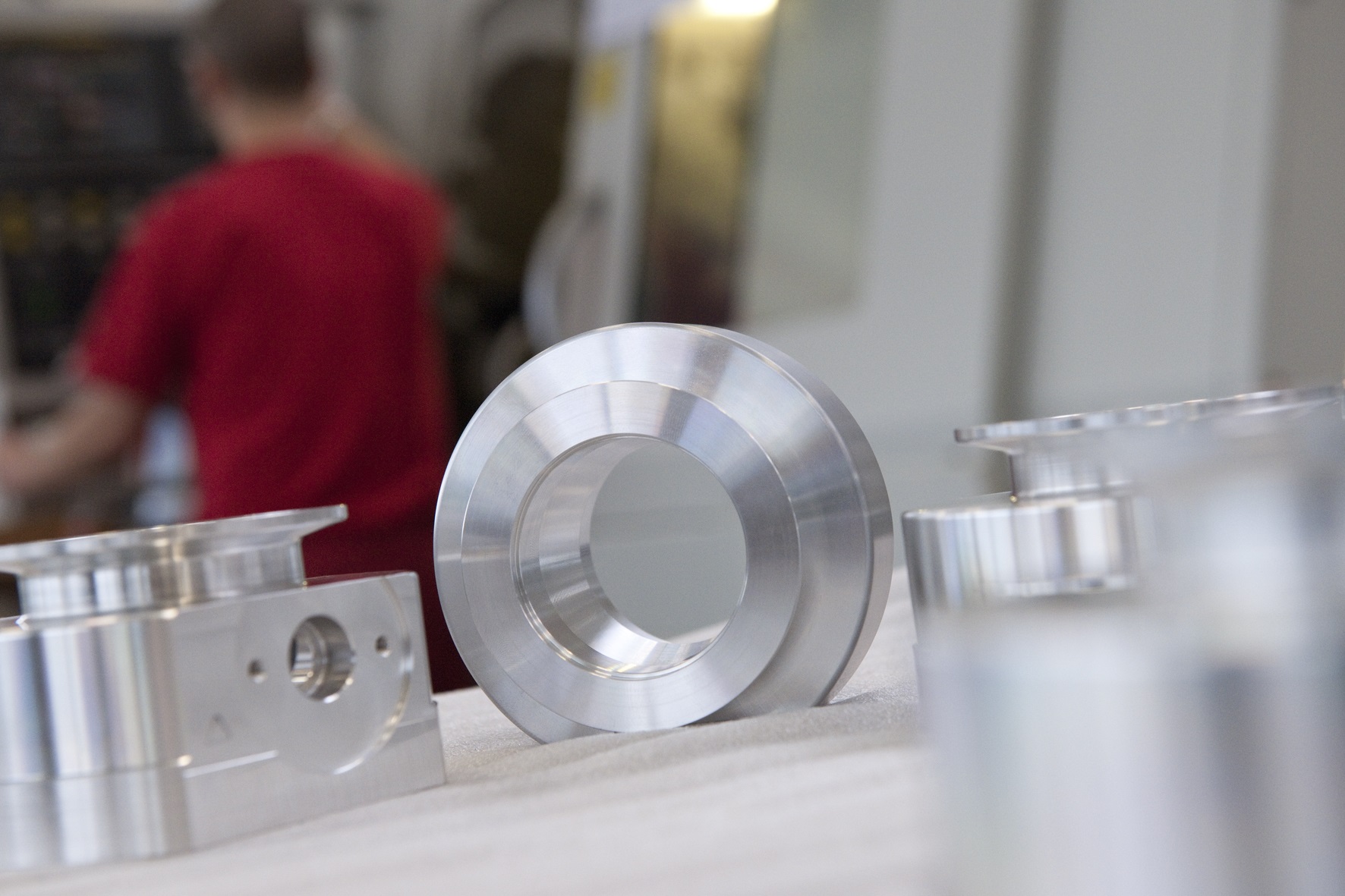

CNC turning

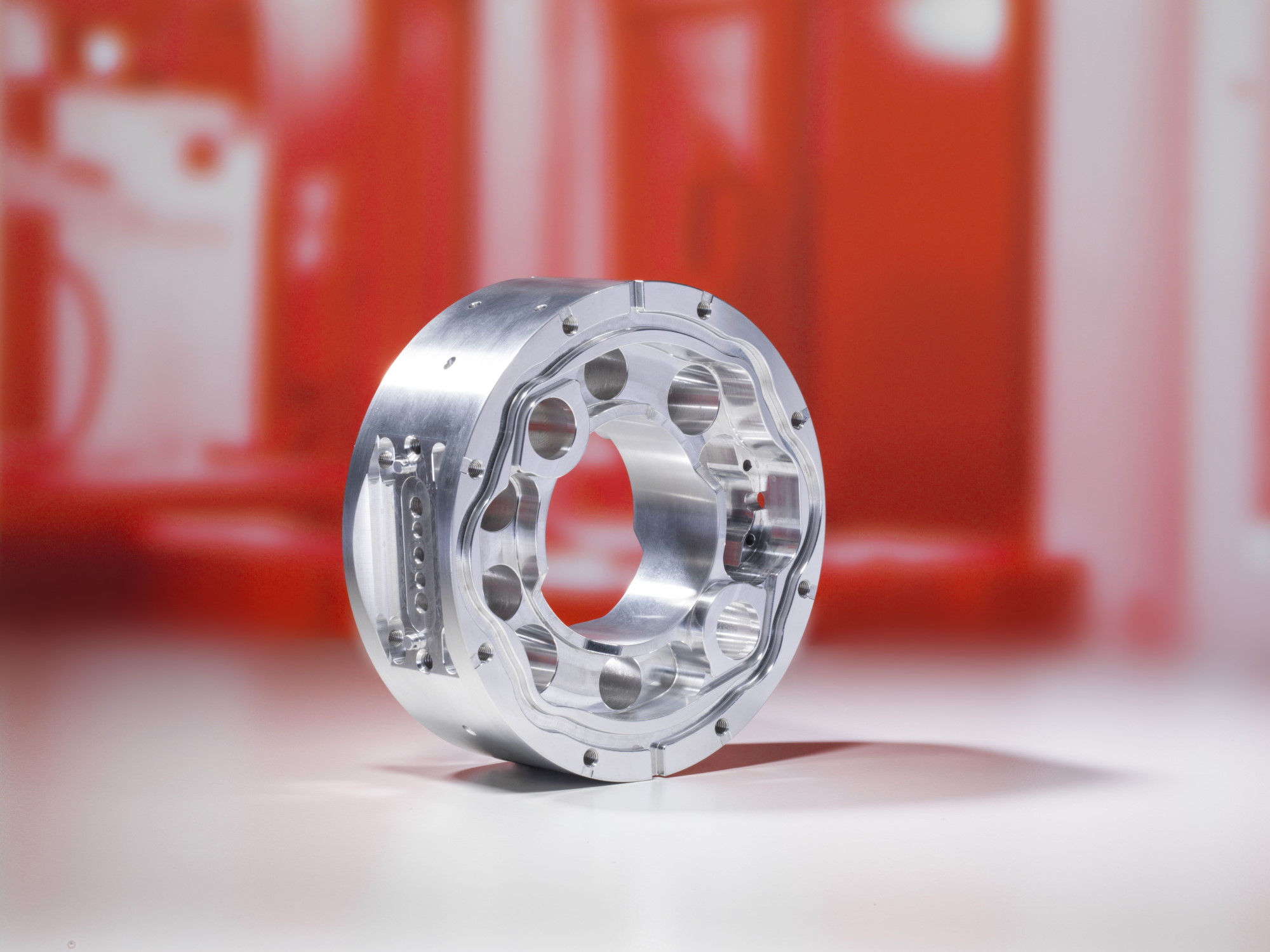

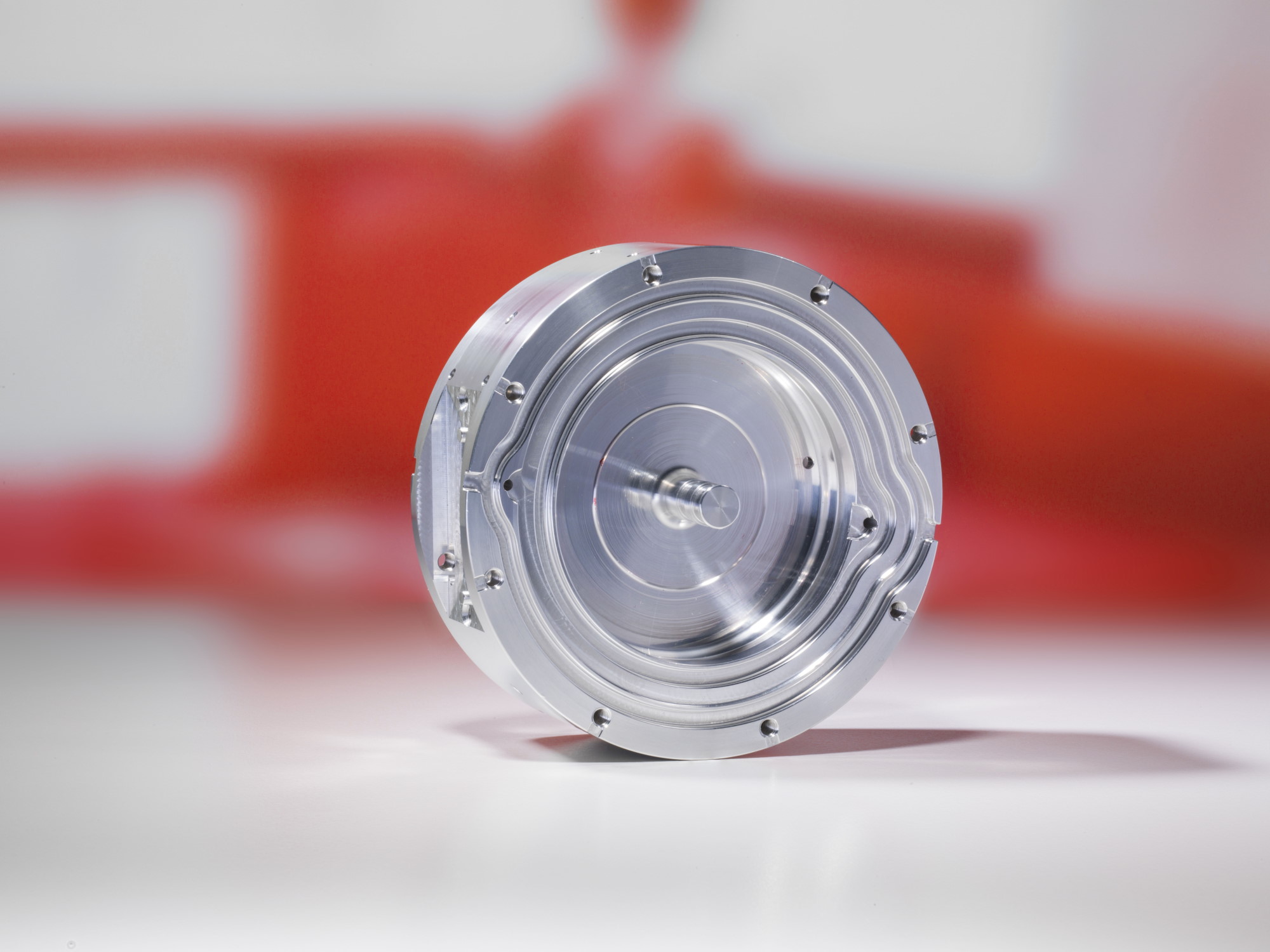

In addition to conventional CNC lathes, our state-of-the-art integrated turning/milling centres exceed the individual machining capabilities of machining centres and CNC lathes. This enables us to offer you increased productivity and outstanding process integration.

- Turning centre

- Turning/milling centre

- Fully automated lathes

- Processing dimensions up to 800x2000mm

- Loading/unloading robots

- Bar loader

- Complex parts production possible

- Small/large series

- 3-shift operation possible

CNC turningIn addition to conventional CNC lathes, our state-of-the-art integrated turning/milling centres exceed the individual machining capabilities of machining centres and CNC lathes. This enables us to offer you increased productivity and outstanding process integration.

|

Grinding

Over 20 years of experience in grinding make us a specialist when it comes to grinding guides, knives, valve seats and much more. Whether hardened steel, ceramics, stainless steel or other – we grind everything to the highest precision.

- 5 profile grinding and surface grinding up to 2 m

- Belt grinding up to 6 m

- Internal and external cylindrical grinding up to Ø 300 mm

GrindingOver 20 years of experience in grinding make us a specialist when it comes to grinding guides, knives, valve seats and much more. Whether hardened steel, ceramics, stainless steel or other – we grind everything to the highest precision.

|

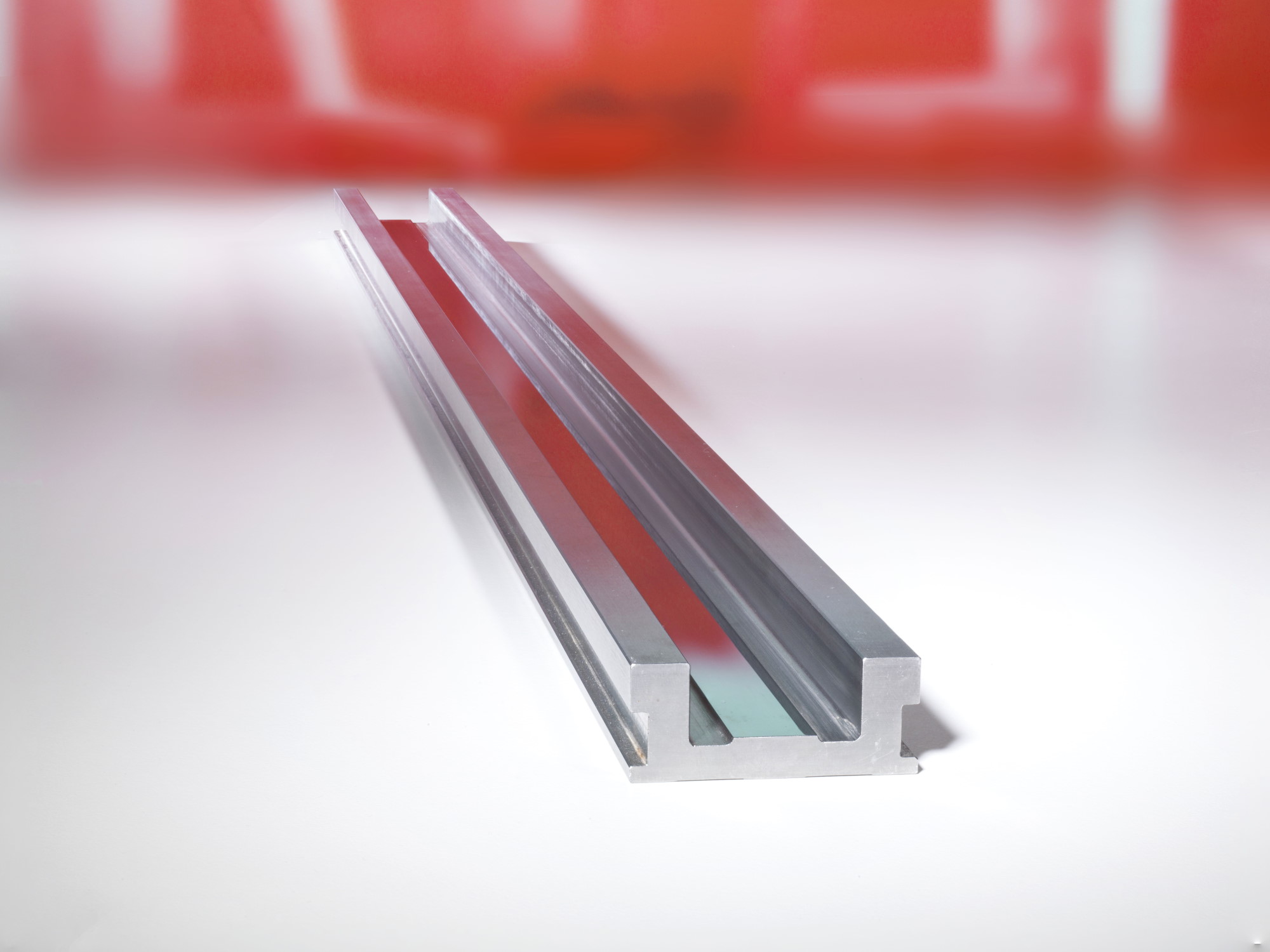

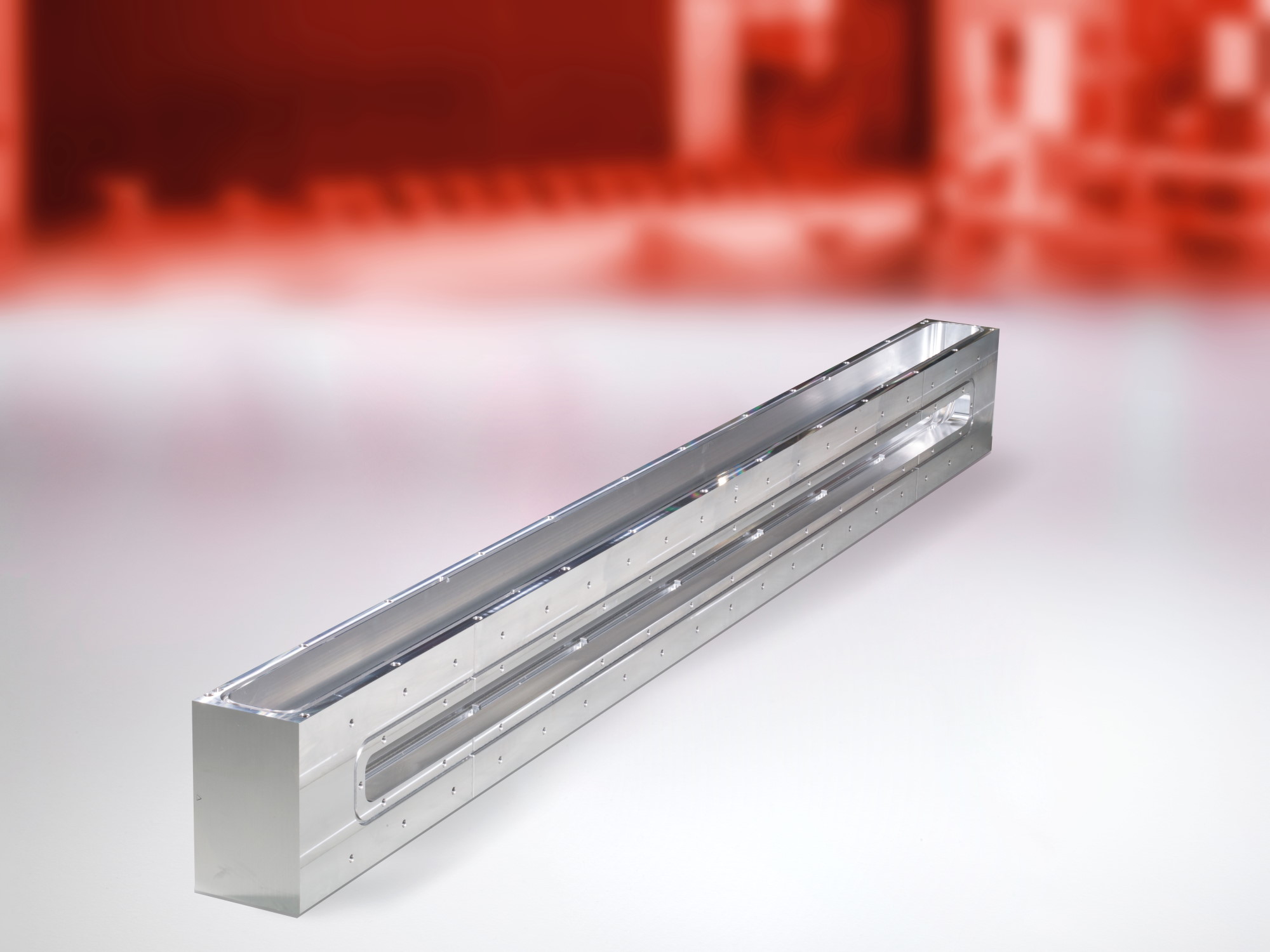

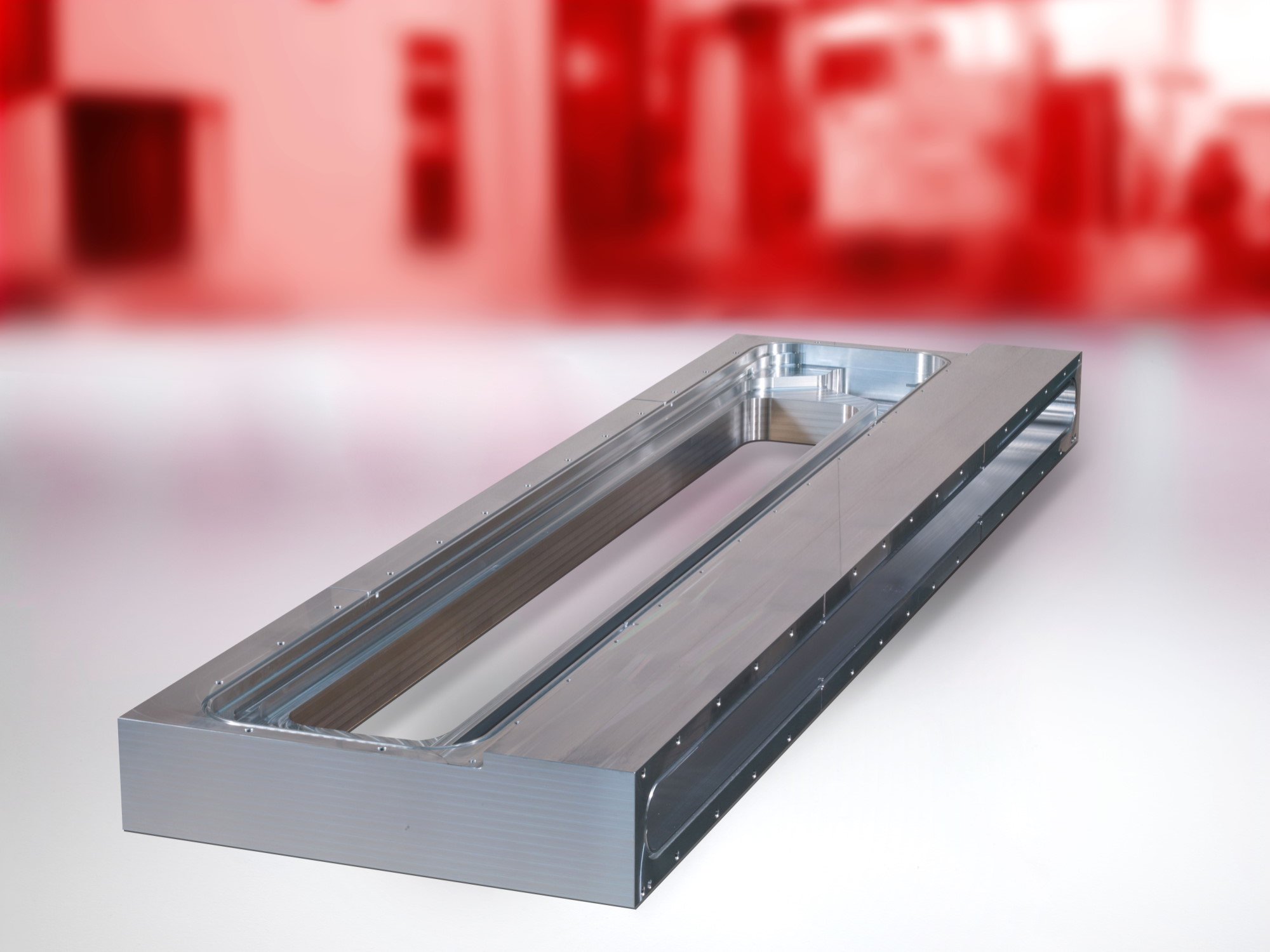

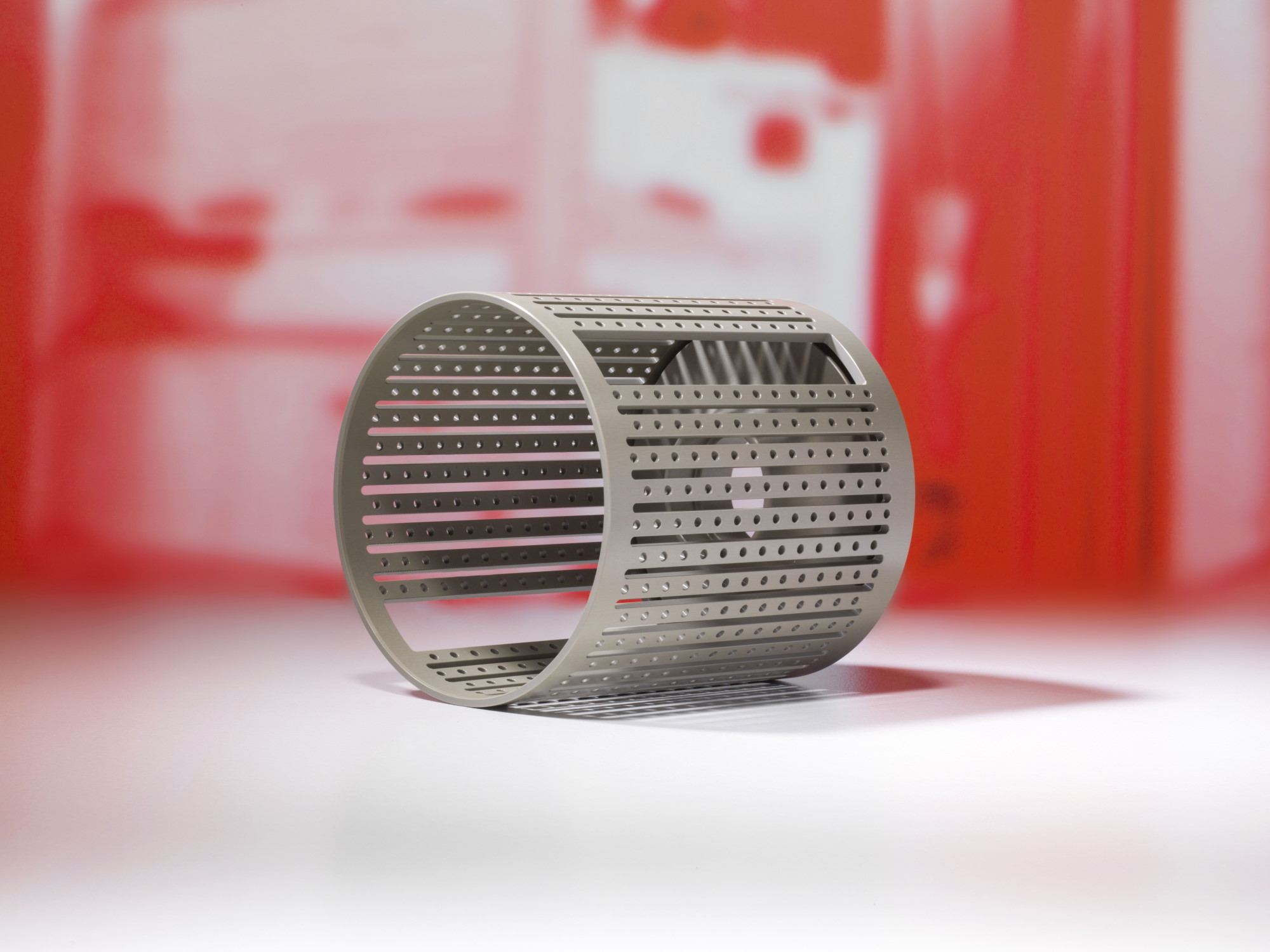

Long parts

Bars, guides, rails or knives, long slender parts are our speciality. Machining possibilities up to 6 meters leave only a few wishes to be desired. Various machines enable machining with highest precision and efficiency.

- Part length up to 6,000mm

- Flexible, cost-effective pre-profiles from our Högg profiles

- Grinding up to 2,000mm

Long partsBars, guides, rails or knives, long slender parts are our speciality. Machining possibilities up to 6 meters leave only a few wishes to be desired. Various machines enable machining with highest precision and efficiency.

|

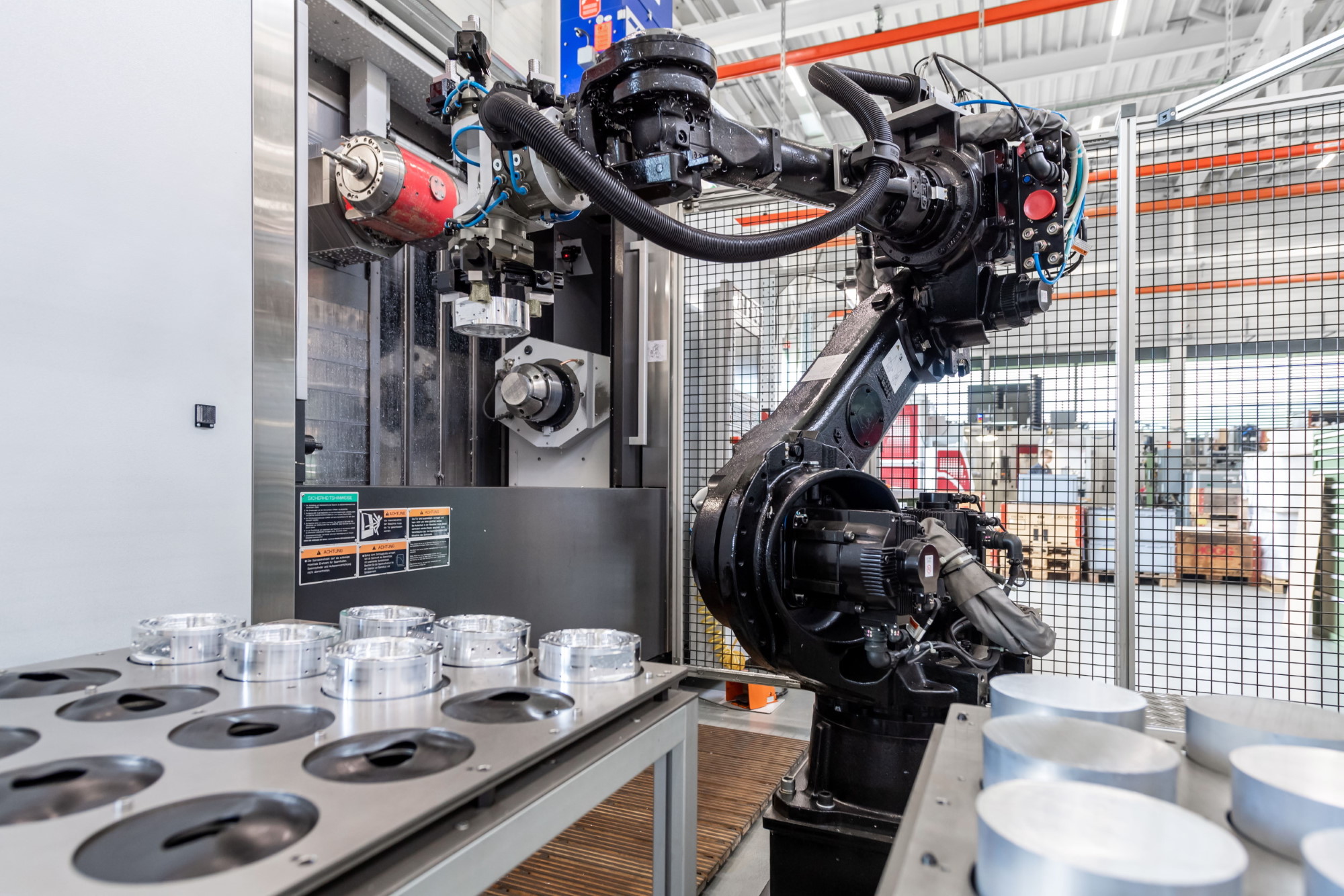

Automated production

On several flexibly automated systems, we can offer you cost-effective milled and turned parts from batch sizes of 100 pieces.

The systems are designed in such a way that they can be set up quickly and easily despite robot handling, so that even smaller batch sizes can be produced fully automatically. Our in-house engineering department (Simplify AG) supports us in this with its broad automation know-how.

- Know-how for special tasks and special cases

- Automated production from a few 100 pieces

- Flexible and cost-effective automation

- Broad automation know-how

- High production capacity (7 x 24h)

- Cost-effective components through automation

Automated productionOn several flexibly automated systems, we can offer you cost-effective milled and turned parts from batch sizes of 100 pieces.

|

Finishing of parts

After the production of the components, many parts require further treatment. We can offer you a variety of further processing in our company:

- Sand/glass bead blasting

- Ultrasonic cleaning (clean room quality ISO 6)/spray cleaning

- Polishing

- Laser marking

- Trowalising (vibratory grinding)

Surface treatments

Additionally, we offer all known surface and heat treatments with external partners. In this way you receive a component that is ready for installation.

- Heat treatments (hardening, annealing, …)

- Anodising (colourless, coloured, hard anodising, …)

- Galvanising, chrome plating, nickel plating, gilding…

- Functional coatings (Balinit,…)

Finishing of partsAfter the production of the components, many parts require further treatment. We can offer you a variety of further processing in our company:

| Surface treatmentsAdditionally, we offer all known surface and heat treatments with external partners. In this way you receive a component that is ready for installation.

|